Fliters

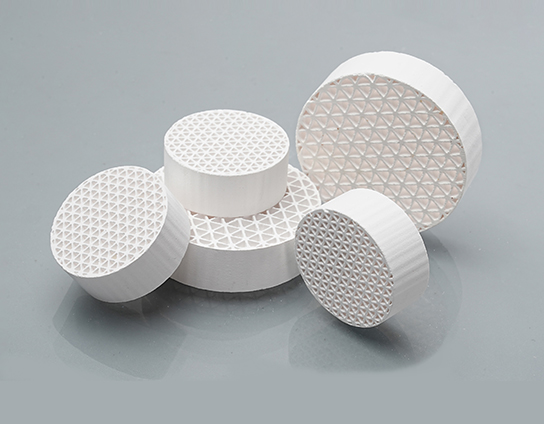

HONEYCOMB FILTER

A kind of porous industrial ceramics

Its internal shape is a number of honeycomb shape parallel channels, these channels

are divided by lattice-like thin walls, widely used in metallurgy, foundry industry metal

melt filtration.

This new ceramic material has a natural chemical adsorption (affinity) for oxides, and

adsorbs impurities in the molten metal (including particles smaller than the pore size)

on the inner wall of the pores, improving the filtration effect. The advanced extrusion

production process makes the ceramic filter have a unique square and triangular design,

which increases the contact area of the material, improves the ability of the filter to

adsorb and capture fine impurities, and has a better filtration effect than the

non-extrusion filter, also the flow of molten metal is stable. Improved pouring speed

and continuity; Reduced casting scrap rate; Improved the mechanical properties of

castings and extend the service life.

Benefits:

High temperature working strength, thermal shock resistance and metal flow impact resistance. No slag or cracking during the operation, which ensures the filtration quality of the molten metal.

Extremely high strength at room temperature and mechanical impact resistance. No cracking or damage during application and transportation, which greatly facilitates the operation of the filter.

Significant filtration effect. Much higher than the filtration effect of a fiber filter. Its remarkable filtration effect is related to the velocity criterion filtration mechanism.

Effectively reduce the turbulence of molten metal brought by pouring, make the filling smooth, and avoid the surface defects of castings.

Large metal flow rate, and stable (unlike the foam ceramic filter, the flow rate gradually decreases with the increase of the number of inclusions to be captured). Even in the case of high inclusions in the molten metal, normal use will not cause clogging of the filter.

High chemical stability, not affected by the acidity and alkalinity of the molten metal, and does not change the chemical composition of the molten metal.

High dimensional accuracy and can be used on the production line of automatic placement of filters. The performance of the ceramic filter is very obviously better than that of the fiber filter, and the fiber filter is inferior to the ceramic filter in terms of filtration effect, reducing the turbulence of molten metal, and high temperature strength. Ceramic filter is the best type of filter selected by foundry manufacturers from the aspects of practicability, reliability, quality and price, etc.