Catalysts

CATALYSTS

Optimal Performance:

By leveraging our advanced R&D platforms, passion for innovation and deep knowledge of materials,

we develop unique, proprietary catalysts and adsorbents solutions that drive customer success.

Product shape:

Spherical, Impeller-shaped, Cylindrical, Porous ball, Trilobe, Quatrefoil, Solid Extrudate, Honeycomb etc.

Hydro Processing Catalyst:

Take our advanced production technology to prepare various hydro processing catalysts, which can flexibly

adjust the type and proportion of activemetals loaded by the catalyst according to customer needs and

meet the requirement of processing different raw materials.

|

Product features: |

High strength/ Reasonable matching of metal components / Suitable acidity |

|

Application: |

Hydro refining of straight-run naphtha, reformed oil, pyrolysis gasoline, coking gasoline diesel, catalytic |

|

Bulk Density: |

0.45-1.30 g/ml |

|

Pore Volume: |

0.1-1.0 ml/g |

|

Surface Area: |

1-380 m2/g |

|

Active Component: |

≥4.0% (single or combinations) |

Adsorbents:

Activated alumina balls have many capillary pores and a large surface area, which can be used as adsorbents, desiccants and catalysts. At the same time, it is also determined according to the polarity of the adsorbed substance, which has a strong affinity for water, oxide, acetic acid, alkali, etc., and the activated alumina ball is a micro-water deep desiccant, and it is also an adsorbent for adsorbing polar molecules. It is widely used in the deep drying and hydrogen production and air separation packaging of petroleum cracking gas and ethylene propylene gas.

The drying of the instrument air dryer and the fluoride treatment in hydrogen peroxide can also remove the exhaust gas Sulfur hydrogen, sulfur dioxide, hydrogen fluoride, hydrocarbons and other pollutant substances are particularly adaptable De fluoridation of fluoridated water.

|

Bulk Density: |

0.68-0.72g/ml |

|

Pore Volume: |

≥0.35ml/g |

|

Surface Area: |

200-350m2/g |

|

Appearance: |

Spherical |

|

AL2O3: |

≥93% |

Guard Catalyst:

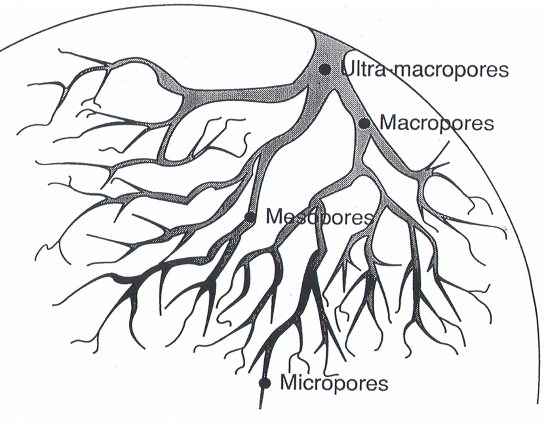

All hydrogenation processes will cause a certain degree of pollution to the catalyst layer, and a large number of impurities contained in the raw oil,such as iron, calcium and carbon-prone substances will be quickly deposited on the highly active Demetallic catalyst, so that the bed pressure dropwill rise quickly. In order to delay the rise of bed pressure drop, it is necessary to install a protective bed that can hold a large amount of iron and coke in the upper part of the Demetallic catalyst bed. Our Guard Catalyst has the characteristics of high strength, large porosity, low internal diffusion resistance, etc., and is loaded on the top of the reactor, which can effectively intercept/capture the particles in the residue, improve the fluid flow state and reduce the bed pressure drop, and can play a good role in protecting the main catalyst.

Scope of application:

It is used in diesel hydro refining, paraffin hydro refining, lubricating oil hydrotreating and supplementary refining, inferior raw oil (heavy oil) hydrotreating and other hydrogenation processes, it usually filled on the top of the reactor in the form of gradation, the main role is to remove particulate matter and Fe, Ca, Na and other impurities in the raw oil, effectively prolong the service life of the main catalyst and delay the rate of pressure drop rise of the catalyst bed, and prolong the operation cycle of the device.